Product Data Quality: 4 Ways to Enhance Product Data

Product data quality sits at the center of modern commerce. From eCommerce sites and marketplaces to ERP systems and printed catalogs, every customer interaction depends...

Published: Aug 8, 2023 Updated: Oct 17, 2025

In today’s product-driven economy, data is the new currency. Yet many businesses struggle to understand where Product Data Management (PDM) ends and Product Information Management (PIM) begins. The two systems sound similar—but serve distinct purposes. Whether you’re a manufacturer, distributor, or retailer, knowing the difference between PDM vs PIM can determine how efficiently your teams collaborate, launch products, and deliver a seamless customer experience.

Product Data Management (PDM) is a system that stores and organizes all product-related technical data generated during the design and engineering stages. It serves as a centralized hub for CAD drawings, bill of materials (BOMs), design revisions, and documentation.

A PDM system is primarily used by engineers and product designers to ensure version control and collaboration across development teams. Think of it as the digital backbone for how a product is built.

PDM platforms come into play long before a product hits the market:

For example, an automotive manufacturer might use PDM software to manage hundreds of CAD assemblies for a single vehicle model. Engineers can make controlled updates without disrupting downstream teams or suppliers.

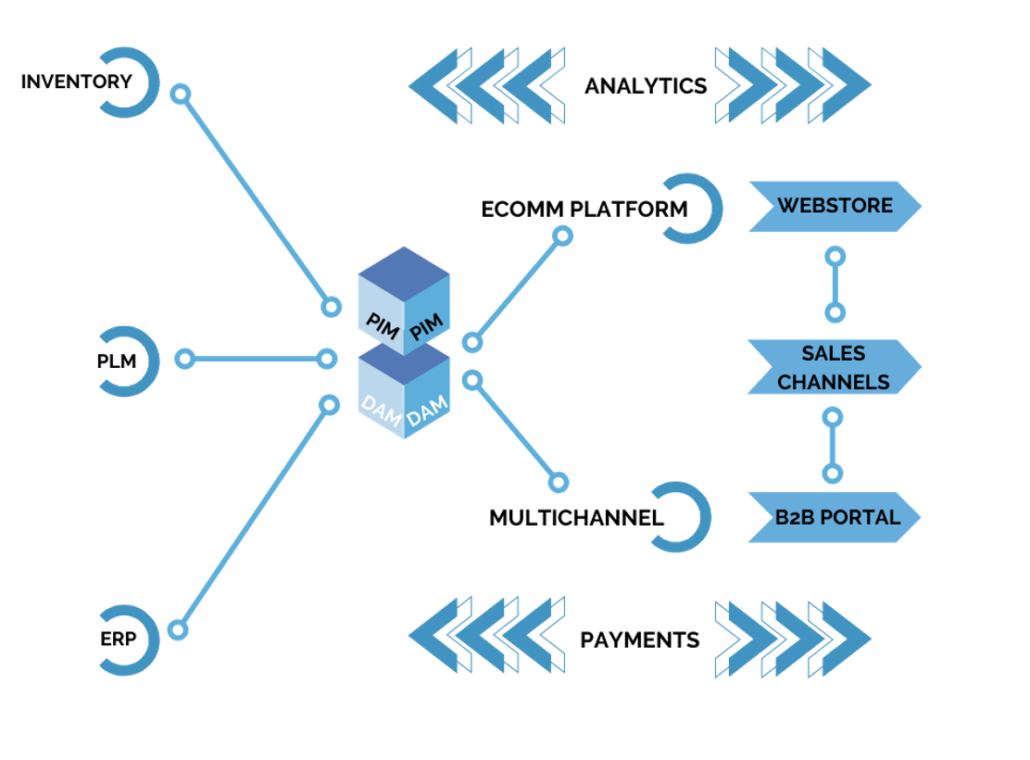

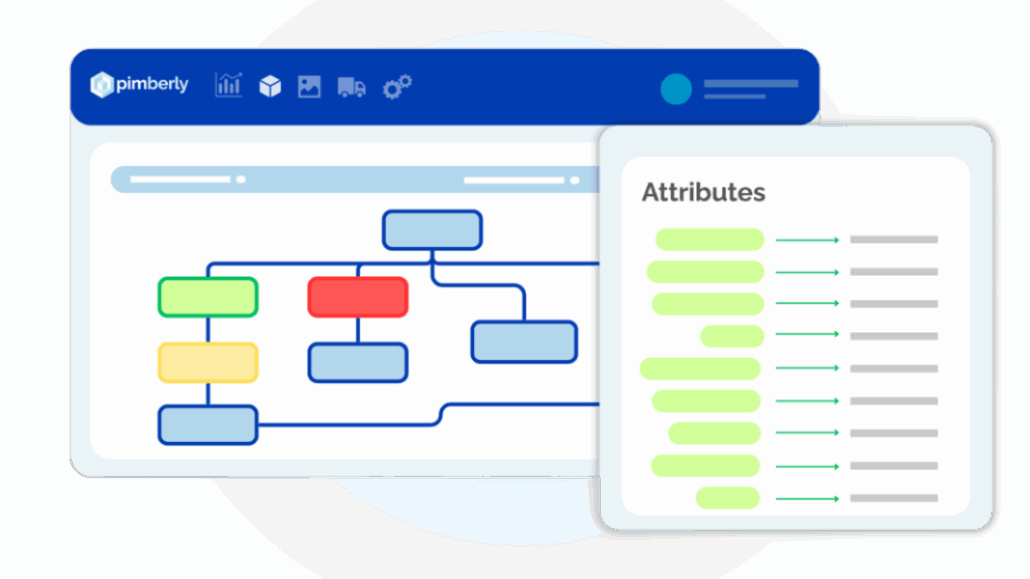

Product Information Management (PIM) is a solution designed to centralize, enrich, and distribute product data across all sales and marketing channels. It consolidates everything a customer or partner needs to buy a product—descriptions, attributes, media files, translations, and pricing—into one source of truth.

A PIM system ensures that consistent, high-quality data flows across eCommerce sites, marketplaces, catalogs, and ERP systems.

Whereas PDM supports the design phase, PIM supports the go-to-market phase:

Imagine a fashion retailer with thousands of SKUs. With a PIM, the team can enrich product data once and instantly push updates to every online storefront, ensuring consistency across all markets.

Understanding the distinction between PDM and PIM isn’t just academic—it’s operational. When engineering, marketing, and eCommerce teams rely on separate systems that don’t communicate, data silos form. These silos slow time-to-market and introduce costly errors.

Without proper integration, product data must be manually transferred from PDM to PIM systems. This often results in duplicated work, mismatched attributes, or missing details when launching new SKUs online.

Integrating PDM and PIM platforms bridges the gap between design and distribution. Once engineering finalizes a product’s specifications in the PDM, that information can automatically flow into the PIM—where marketing teams can enrich it for public-facing channels.

By aligning both systems, you eliminate redundant entry, reduce errors, and accelerate launch cycles.

When organizations harmonize engineering and marketing data, they unlock major business advantages:

Automated data flow between PDM and PIM systems means new products can move from prototype to storefront faster. Engineering approvals instantly trigger updates downstream, cutting launch timelines from weeks to days.

Consistency is critical in omnichannel commerce. A single error—like a mismatched size or outdated material—can result in customer dissatisfaction and costly returns.

By integrating PDM’s technical data with PIM’s enriched marketing content, you maintain one synchronized source of truth.

PDM and PIM integration fosters transparency across departments:

This cross-functional visibility improves efficiency and fosters a culture of data ownership.

In industries such as manufacturing, apparel, and electronics, compliance requirements are growing. Regulations like the EU Digital Product Passport (DPP) will soon require detailed product traceability.

By aligning PDM and PIM, companies can track every component from design to disposal, ensuring transparency for regulators and consumers alike.

Learn more about how Pimberly supports DPP readiness through its AI-powered data workflows in related resources on our site.

When evaluating systems, focus on capabilities that enhance collaboration and automation between the two.

A modern PIM platform like Pimberly combines these strengths—offering an extensible API that connects seamlessly with PDM, ERP, and DAM systems for complete product lifecycle visibility.

Consider a global electronics manufacturer.

In PDM: Engineers store circuit designs, materials lists, and version-controlled CAD models.

In PIM: The marketing team enriches these details with descriptions, certifications, lifestyle imagery, and regional translations.

Together: When a new version is approved in PDM, the change syncs automatically to PIM, triggering updated listings across all marketplaces.

This unified approach not only streamlines internal operations but also improves the customer experience—customers always see accurate specifications, pricing, and availability.

At their core, both PDM and PIM aim to deliver trustworthy product data.

But the PIM system plays a uniquely visible role in customer engagement. It ensures that every digital touchpoint—whether your eCommerce store, Amazon listing, or printed catalog—reflects the same high-quality information.

Without a PIM, even the most advanced PDM system leaves a gap between what’s designed and what’s sold. By using a PIM platform like Pimberly, companies can:

To see how Pimberly helps brands transform product data into customer-ready experiences, explore our overview of Product Information Management.

Q: Can PDM replace a PIM system?

A: No. PDM handles technical design data for engineers, while PIM manages marketing-ready product information. They complement—rather than replace—each other.

Q: Do I need both systems?

A: If your business designs products and sells them online, yes. PDM ensures your engineering data is accurate; PIM ensures your customer data is engaging and consistent across channels.

Q: How does a PIM integrate with a PDM?

A: Modern platforms use APIs or middleware to sync approved product data automatically. For example, once a part number or specification is finalized in PDM, it can populate attributes in PIM without manual input.

Q: What happens if you don’t connect PDM and PIM?

A: Data duplication, slower product launches, and inconsistent customer experiences. Integrating the two ensures accuracy from the first CAD drawing to the final online listing.

To summarize:

For businesses navigating digital transformation, the synergy of PDM and PIM drives:

If your teams are juggling disconnected systems, it may be time to unify them.