What products to restock

You may have to go above and beyond with inventory replenishing, according to the amount of SKUs you sell. Knowing which products are selling more quickly than others can enable you to adjust inventory levels in response to demand and is known as an inventory restocking method.

This makes it easier to avoid stocking an identical quantity of every product, even if some may sell more slowly than others. It’s also possible that some SKUs don’t sell well, in which case stopping them could save you money. You can also learn where demand is highest by putting strategies in place to obtain complete visibility into inventory levels particularly if you keep products across several locations.

What entails restocking products?

Inventory restocking is a crucial component of inventory optimization, but it can be difficult when future events are unpredictable. Demand is unpredictable and can change at any time, whether it’s in the run-up to the holiday shopping period or when a social media user shares your product with people they follow.

On the other hand, there are methods for strategically replenishing inventories based on SKU-level knowledge. This is a summary of what inventory replenishment entails. Knowing when and how often to refresh inventory is the key to optimizing your replenishment cycle.

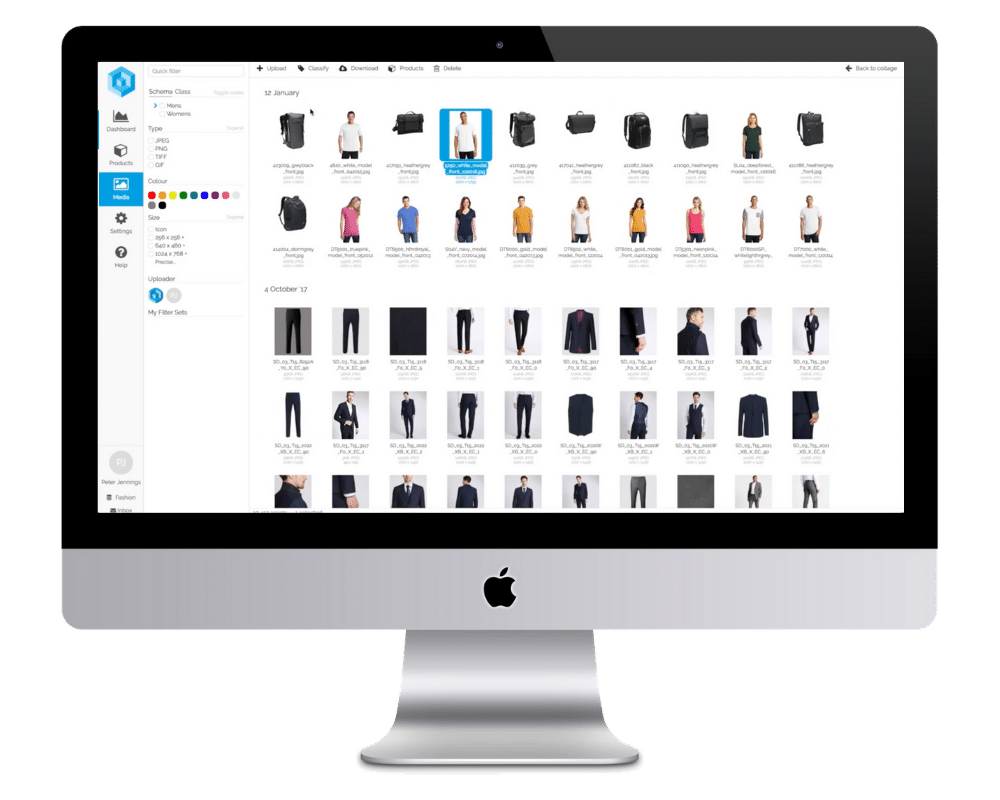

Implementing tools and technologies that track inventory data in real time is crucial for making strategic decisions, particularly because eCommerce inventory moves throughout the supply chain continuously and frequently experiences delays.

How to design a restocking process

Technology and teamwork are necessary for effectively and swiftly replenishing inventory. Restocking inventory involves more than just placing new orders for supplies; you also need to think about how you store and receive inventory as well as the speed at which you can make it ready for sale.

A larger order for inventory may be placed if you plan to scale up. Will there be enough room for it? Will your warehouse need to be reorganized or re-racketed? Modifying the layout of a warehouse can need careful planning and a lot of work.

The effectiveness with which you handle your reorder point is another procedure that affects inventory replenishment. It is imperative to expedite the processing of returns to ascertain the quantity of returnable items that can be restocked for prospective sales.

To help you in understanding what products to restock at the SKU level, there are a variety of inventory tools available on the market that make it simple to estimate demand based on previous sales trends. Remember that you will also need to consider deadlines for various phases of the supply chain, such as the length of time it takes for your supplier to deliver merchandise to you and the speed at which your team can get the store inventory on the shelves.

How does inventory management software work?

One of the numerous ways an extensive inventory management software benefits retailers is by helping you understand how to decide what products to restock. Retailers may increase stock availability, control inventory costs, and boost customer happiness by automating the procedures that support inventory refilling and using data to inform replenishment decisions using Inventory Management Software.

The ability to examine inventory information in real-time for every location and sales channel facilitates more effective replenishment management for inventory optimization. Using demand-based planning based on historical data, sales predictions, and seasonality, an inventory management software dynamically manages reorder points to maximize stock availability. Support for chosen, periodic cycle counts further contributes to the accuracy and ease of use of inventory information.

For many shops, handling inventory refilling can be difficult. However, improving lean time replenishment can result in increased productivity, client happiness, profitability, and revenue growth while also helping you meet customer demand adequately. Retailers may implement efficient stock replacement procedures that keep them ahead of both client demand and the competition with the correct data, inventory restocking strategy, and inventory management technology.

How to manage inventory stockouts

Your store’s bottom line may suffer from ineffective inventory replenishment procedures, which can lead to overspending on transportation expenses and missed sales. You’ll encounter several inventory management problems that could affect inventory replenishing if you don’t put stock control procedures into place and increase inventory accuracy.

You run the danger of having to deal with stockouts when you don’t order profit based products on time and are unaware of the best products to restock. Costs associated with stockouts can be high, particularly if they occur frequently and result in lost business, canceled orders, and perhaps even unfavorable internet reviews.

Determining the appropriate amount of safety stock to keep on hand is one of the numerous strategies to prevent stockouts. In this manner, you will have excess inventory to prevent fulfillment delays in the event of an unexpected spike in demand. You should also consider supply chain concerns, as shipping internationally has its own set of difficulties such as port delays. Therefore, it is imperative to initiate capable inventory management tools and software to help you keep an eye on your inventory in real time.

Effective restocking strategies

Here are the three most important restocking strategies:

Leverage Inventory Data

You may forecast future demand, evaluate historical trends, and modify your inventory levels using inventory data. Brands can also use inventory data for other purposes, such as reporting on inventories or scheduling the lead time of your next promotion.

Utilize an Inventory Management System

Inventory management software is used by the majority of online firms to expedite order processing, distribution, and inventory management. By eliminating manual labor and automating inventory tracking, inventory management software can additionally save time by lowering human error.

Implement Regular Inventory Audits

By carrying out inventory audits, you can determine profit margins, spot inefficiencies or shrinkage in your inventory, and adjust your order in accordance with your lead time. You can do this by simply counting your physical stock and comparing it to your estimation of how much you should have.

Bottom line

Understanding how to effectively restock your merchandise and inventory is crucial for a successful running business. You can work on the efficient strategies mentioned above or you can also incorporate technologically elevated management tools to help you optimize your restocking process. Contact us at Pimberly to avail the best management tools around you.